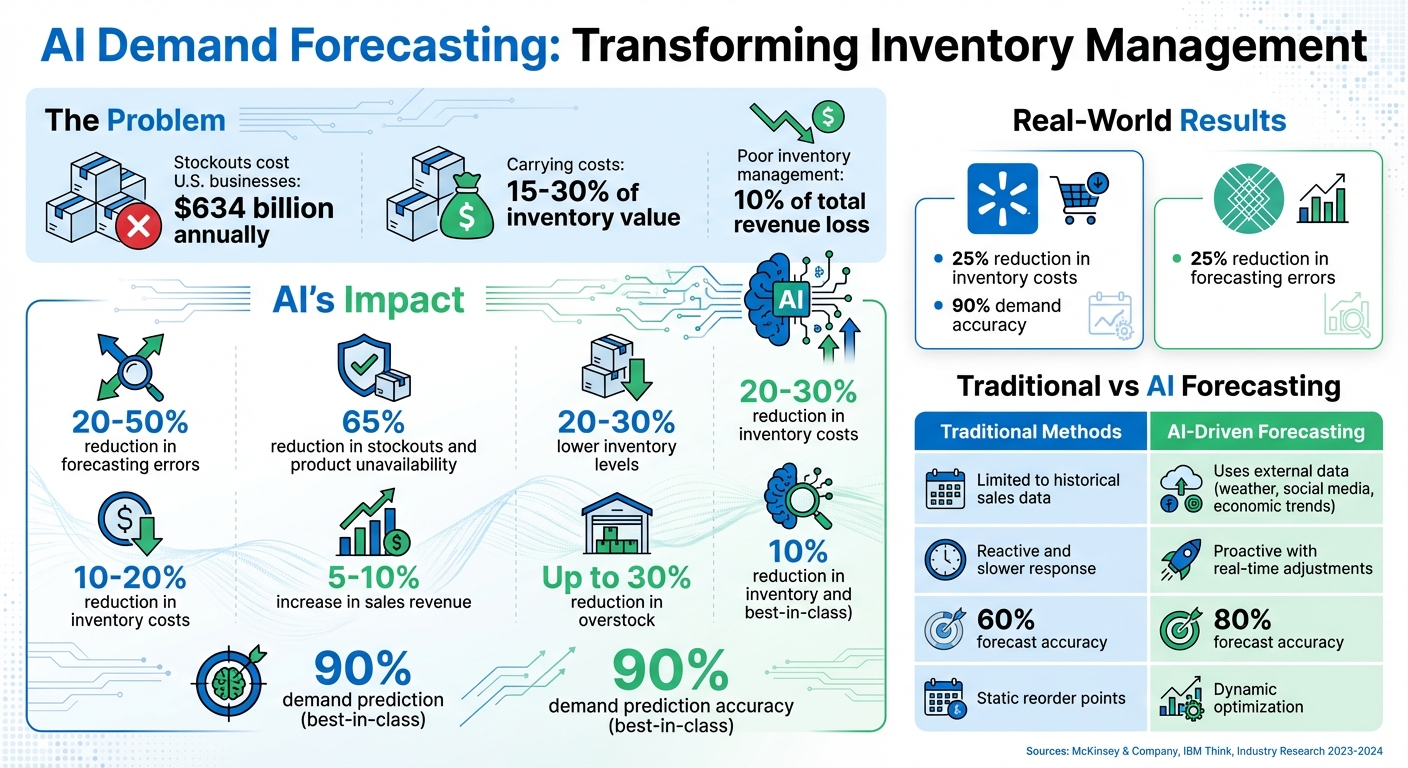

AI is transforming inventory management by improving forecasting accuracy, reducing costs, and speeding up inventory turnover. Businesses that use AI-driven demand forecasting can cut forecasting errors by up to 50%, reduce stockouts by 65%, and lower inventory levels by 20-30%. This leads to fewer lost sales, less excess inventory, and better cash flow.

Here’s why AI demand forecasting matters:

- Inventory turnover tracks how often stock is sold and replenished. Low turnover can lead to wasted resources and high carrying costs (15-30% of inventory value).

- Stockouts cost U.S. businesses $634 billion annually. AI helps predict demand and ensures products are available when needed.

- AI uses external data like weather, social media, and economic trends to make forecasts more precise and adjust in real-time.

- Companies like Walmart and Stitch Fix have seen significant improvements, cutting inventory costs by up to 25% and reducing forecasting errors by 25%.

AI doesn’t just predict demand - it optimizes reorder points, reduces excess inventory, and ensures faster inventory cycles. By integrating AI tools into your operations, you can improve efficiency, increase sales, and save costs.

Key benefits:

- Reduce lost sales and stockouts

- Lower excess inventory and carrying costs

- Improve forecasting accuracy and turnover rates

AI demand forecasting is reshaping inventory management, making it faster, smarter, and more effective.

AI Demand Forecasting Impact on Inventory Management: Key Statistics and Benefits

How AI Improves Inventory Turnover: Research and Case Studies

Research Findings on AI's Impact

AI is transforming inventory management with striking results. According to McKinsey & Company, AI-powered forecasting can cut supply chain errors by 20% to 50% and reduce product unavailability by up to 65%. Businesses using AI report a 10–20% drop in inventory costs while enjoying a 5–10% boost in sales. Machine learning, in particular, has proven its worth by reducing excess stock by as much as 20% and improving forecast accuracy by 20–25% compared to traditional statistical methods.

Advanced AI systems take these benefits even further. For example, the MARIOD multi-agent reinforcement learning framework demonstrated an 18.2% reduction in forecast errors and a 23.5% drop in stockout rates compared to standard approaches. These advancements ensure products are delivered precisely when needed, speeding up inventory turnover and improving overall efficiency.

While research highlights the potential, real-world examples bring these numbers to life.

Real-World Examples of AI Success

The impact of AI becomes even clearer when looking at how companies are applying it. Take Stitch Fix, for example. This personalized clothing service uses AI-driven forecasting to fine-tune its inventory management. By adopting this technology, Stitch Fix reduced forecasting errors by 25%, leading to better supply chain efficiency. For a business handling millions of custom clothing shipments, this level of precision makes a significant difference in how quickly inventory moves through the system.

Similarly, Walmart has embraced AI with a cloud-based inventory system that analyzes weather patterns to optimize emergency stock levels. This approach has cut inventory costs by 25%. By predicting demand spikes caused by storms or seasonal changes, Walmart ensures that products are available when customers need them, balancing just-in-time delivery with reduced carrying costs.

Comparing AI Forecasting to Manual Methods

The difference between AI-driven and manual forecasting methods is stark. Traditional systems rely heavily on historical sales data and assume trends will continue in a straight line. This approach often fails during periods of market volatility or unexpected events. In contrast, AI systems can analyze a wide range of external factors - like weather, social media trends, and economic shifts - to identify complex patterns that manual methods overlook.

| Feature | Traditional Methods | AI-Driven Forecasting |

|---|---|---|

| Data Sources | Limited to historical sales and current orders | Combines internal sales with external factors (e.g., weather, social media, economic data) |

| Response Time | Reactive and slower | Proactive with near real-time adjustments |

AI-driven forecasting not only reduces stockouts and surplus inventory but also speeds up the entire inventory cycle. By bridging the gap between demand prediction and inventory management, these systems ensure businesses can respond faster and more effectively to changing conditions. This sets the stage for understanding how AI doesn't just improve forecasts - it fundamentally accelerates inventory turnover.

AI Demand Forecasting: Boost Accuracy, Protect Capital & End Guesswork in Manufacturing

How AI Drives Faster Inventory Turnover

AI is revolutionizing the way businesses manage their inventory cycles, turning slow, reactive processes into fast, proactive systems. It doesn’t just predict demand - it reshapes how companies handle inefficiencies that typically drag down inventory turnover. From sharper forecasting to real-time adjustments and smarter reordering, AI creates a seamless flow that keeps inventory moving.

Better Forecast Accuracy and Lower Error Rates

One of AI’s most impactful contributions is its ability to slash forecasting errors. Traditional methods, like ARIMA models or spreadsheet-based systems, often fall short in today’s complex retail environment. With thousands of SKUs and unpredictable market trends, these older tools can’t keep up. AI-driven algorithms like LSTM and XGBoost, however, excel at identifying complex, non-linear demand patterns that manual methods miss.

AI has pushed forecast accuracy rates from 60% to as high as 80%. For example, Idaho Forest Group cut their forecasting time from over 80 hours to less than 15 by adopting AI-powered tools. For companies managing massive inventories, even small gains in accuracy can dramatically reduce both stockouts and excess inventory.

"AI-driven forecasting systems learn dynamically - meaning they are iterative and continuously improving. Machine learning algorithms identify relationships within data that are too complex or nonlinear for traditional forecasting methods to capture." – IBM Think

AI doesn’t stop at making predictions; it also monitors its own performance. Metrics like MAPE (Mean Absolute Percentage Error) and bias tracking help businesses pinpoint areas for improvement, ensuring that inaccuracies are addressed before they disrupt inventory levels.

This precision is further amplified when AI incorporates real-time data into the mix.

Using External Data and Real-Time Signals

Traditional forecasting focuses heavily on historical sales data, which can leave businesses blind to current market shifts. AI-powered systems, on the other hand, bring in external factors like weather changes, social media trends, economic conditions, holiday schedules, and even local events. This broader view creates a more accurate picture of demand drivers.

Take Walmart, for instance. By integrating AI-driven demand sensing - analyzing everything from customer purchasing habits to weather patterns - they boosted demand prediction accuracy by up to 90% and cut inventory costs by 25%.

Similarly, Novolex, a packaging manufacturer, combined historical sales data with supply chain and market indicators. The result? A 16% drop in excess inventory and a shift from weeks-long planning cycles to just days. With AI’s real-time processing, businesses can make same-day inventory decisions, avoiding costly delays.

These real-time insights pave the way for smarter, more dynamic inventory strategies.

Optimizing Reorder Points and Safety Stock Levels

AI doesn’t just forecast demand - it takes the next step by optimizing how inventory is replenished. Traditional systems often rely on static safety stock levels and fixed reorder points, which can lead to either overstocking or stockouts. AI replaces these outdated rules with dynamic adjustments based on real-time data, lead times, and external conditions.

Using stochastic optimization, AI minimizes costs while meeting service goals. This approach has proven effective, reducing inventory levels by 10% to 35%. AI systems continuously recalculate reorder points, adapting to supplier delays, seasonal trends, or promotions without needing manual input.

In fact, AI-powered tools can cut overall inventory levels by 20% to 30%, freeing up capital that would otherwise sit idle in warehouses. By analyzing multivariate data - like pricing, promotions, and even weather - algorithms such as XGBoost pinpoint the perfect moment to reorder each SKU. This ensures inventory moves swiftly through the supply chain, arriving exactly when it’s needed.

Platforms like Forthcast exemplify this dynamic approach. By adjusting safety stock and reorder points in real time, Forthcast helps businesses maintain lean, responsive inventories. It uses statistical analysis to recognize patterns and machine learning to adapt, selecting the best forecasting method for each SKU. With features like anomaly detection and custom forecast enrichments for promotions, Forthcast brings cutting-edge AI techniques to businesses without requiring a dedicated data science team.

sbb-itb-499c055

Research on Stockouts, Excess Inventory, and Turnover Rates

AI-driven forecasting is transforming how businesses manage inventory, tackling stockouts, reducing surplus, and improving turnover rates. Let’s dive into how these advancements are delivering measurable results.

Reducing Stockouts and Lost Sales

Stockouts are a costly problem. In the U.S. alone, they account for approximately $634 billion in lost sales annually. When products are unavailable, customers often turn to competitors. AI-powered forecasting mitigates this by predicting demand shifts and reducing stockouts.

According to McKinsey, AI forecasting can cut product unavailability and lost sales by up to 65%. Instead of reacting to stockouts after the fact, AI systems analyze subtle demand signals - like weather patterns, social media trends, and local events. This allows businesses to adjust inventory levels in real-time, preventing disruptions before they occur.

For example, an e-commerce retailer implemented real-time monitoring and automated reordering through an AI platform, achieving a 25% reduction in stockouts and a 15% decrease in inventory holding costs.

"Applying AI-driven forecasting to supply chain management... can translate into a reduction in lost sales and product unavailability of up to 65 percent." – McKinsey & Company

AI also cuts the need for costly emergency measures. Traditional systems often lead to expensive rush shipping when stockouts happen, increasing costs by as much as 50%. By ensuring timely reordering, AI not only avoids these extra costs but also improves product availability, leading to a 5% to 10% boost in sales.

Cutting Excess and Obsolete Inventory

Excess inventory locks up resources, immobilizing 30% of its value, while carrying costs range from 15% to 30%. Obsolete stock, often marked down or written off, further erodes profit margins.

AI helps balance inventory by continuously analyzing demand and refining recommendations. Retailers using predictive analytics have reported up to a 30% reduction in both overstock and stockouts.

Take Walmart, for instance. Their AI-driven demand sensing system integrates real-time data with external signals, improving demand accuracy by up to 90% and significantly cutting surplus inventory. Similarly, Zara uses real-time demand data to guide 85% of its manufacturing, allowing the company to quickly respond to trends and minimize unsold stock.

By eliminating the guesswork of traditional forecasting, AI reduces over-ordering caused by human bias, streamlining inventory and improving turnover metrics.

Improving Inventory Turnover Metrics

By tackling stockouts and excess inventory, AI creates a more efficient inventory cycle. Faster turnover means capital is freed up, and storage costs drop. AI-driven forecasting accelerates turnover by addressing both shortages and surpluses simultaneously.

The financial benefits are clear. Higher turnover rates reduce costs tied to storage, insurance, and maintenance. AI models have been shown to cut logistics costs by 31.5% and reduce unused fleet mileage by 15%. On the procurement side, companies using AI-driven inventory management report up to a 15% reduction in procurement costs.

For example, Novolex used AI to blend historical data with market insights, reducing excess inventory by 16% and shortening planning cycles from weeks to just days.

| Metric | Impact of AI Adoption | Source |

|---|---|---|

| Reduction in Lost Sales/Unavailability | Up to 65% | McKinsey |

| Reduction in Forecasting Errors | 20% - 50% | McKinsey/Oracle |

| Increase in Sales Revenue | 5% - 10% | |

| Reduction in Inventory Costs | 10% - 20% | |

| Reduction in Overstock/Stockouts | Up to 30% | VusionGroup |

Forthcast applies these proven strategies to optimize inventory management. By combining statistical analysis with machine learning, it selects the best forecasting model for each SKU. Features like anomaly detection, custom forecast adjustments for promotions, and automated reorder alerts ensure inventory flows smoothly, reducing stockouts and excess while improving turnover rates.

How to Implement AI Demand Forecasting

What You Need for Effective AI Forecasting

To make AI demand forecasting work, you need a solid foundation of clean, centralized data. This data typically comes from systems like OMS (Order Management Systems) or ERP (Enterprise Resource Planning), which consolidate sales figures, product details, and warehouse metrics.

But relying solely on internal data won’t cut it. External factors like weather patterns, social media sentiment, economic trends, and competitor pricing play a big role in improving forecast accuracy. For example, an IBM survey revealed that 90% of executives expect AI and automation to be deeply integrated into supply chain workflows by 2026.

Bringing together a cross-functional team is just as important. Involving people from sales, marketing, finance, and supply chain ensures accountability and helps interpret the insights AI provides. To measure how well your forecasting system is working, use metrics like Mean Absolute Error (MAE) and Root Mean Squared Error (RMSE). These benchmarks allow you to evaluate performance and fine-tune your models.

Once you have the right data and team in place, the next step is tackling common challenges that come with implementation.

Addressing Common Implementation Challenges

One major hurdle is dealing with data gaps, especially for new SKUs that lack historical sales data. Traditional forecasting methods often fail here. AI steps in with tools like Random Forest models, which analyze similar products and market trends to generate predictions. Another challenge is managing extreme seasonality, such as holiday sales spikes or weather-driven demand fluctuations. Long Short-Term Memory (LSTM) networks excel in these scenarios by identifying long-term patterns and seasonal trends.

Resistance to change is another obstacle. A good way to overcome this is to start small - pilot AI in one product category or region. This allows you to set benchmarks and prove ROI before scaling up. Plus, modern AI systems can deliver results in as little as six months, compared to the 18–24 months typically needed for older platforms.

Lastly, ensure data quality by pre-processing to remove outliers. Clean data leads to more reliable forecasts.

Platforms like Forthcast are designed to address these challenges head-on, offering proven AI tools to simplify implementation.

How Forthcast Applies AI Research to Inventory Management

Forthcast builds on these principles to tackle inventory management challenges using advanced AI techniques.

The platform uses a mix of statistical methods and machine learning to select the most accurate forecasting approach for each SKU. For its 6-month demand projections, Forthcast relies on LSTM models to identify seasonal trends and long-term patterns. It also includes anomaly detection to flag unusual sales activity, such as sudden demand shifts caused by changes in consumer sentiment or weather events. This allows businesses to adjust inventory ahead of time.

Forthcast integrates seamlessly with existing Order Management Systems, sending automated reorder alerts based on real-time stock levels and forecast-driven thresholds. It also handles tricky scenarios like bundle management by breaking down bundled items into individual SKU forecasts for better planning. For new products without sales history, Forthcast substitutes data from similar, well-established products to create accurate forecasts.

To top it off, the platform tracks both forecast bias and accuracy, giving users a clear view of how the models are performing. This transparency helps businesses continuously refine their inventory strategies and make smarter decisions.

Conclusion

AI-driven demand forecasting is reshaping how e-commerce businesses handle inventory. Studies reveal that AI can lower inventory costs by 10–20%, increase sales by 5–10%, and reduce forecasting errors by 20–50%, tackling challenges like stockouts and overstocking head-on. These numbers highlight the potential for businesses to adopt actionable AI strategies.

By moving from reactive to proactive inventory management, businesses can anticipate customer needs rather than just responding to problems. AI uses external data and real-time signals to uncover demand patterns that traditional methods often miss. This shift doesn’t just improve accuracy - it leads to tangible results, like faster inventory turnover. AI has been shown to reduce overall inventory levels by 20–30% and cut stockouts by as much as 65%.

These advancements are more than just theoretical - they’re practical. Tools like Forthcast bring these AI techniques to life, offering features like 6-month demand forecasts, anomaly detection, and automated reorder alerts. Companies like Walmart, which achieved 90% demand prediction accuracy, and Stitch Fix, which reduced forecasting errors by 25%, demonstrate the real-world impact of these technologies. For businesses where poor inventory management can eat up 10% of total revenue, adopting AI isn’t just smart - it’s a competitive necessity.

FAQs

How does AI improve demand forecasting accuracy compared to traditional methods?

AI transforms demand forecasting by diving deep into massive amounts of real-time and historical data. It pulls insights from sources like sales trends, economic signals, weather conditions, and even social media buzz. With the help of advanced machine learning models, it uncovers patterns that might go unnoticed otherwise and continuously refines its predictions as new data rolls in.

This smarter, adaptive method can cut forecast errors by an impressive 20% to 50% compared to older techniques like spreadsheets or static models. The result? Businesses can make smarter inventory choices, reducing the risk of running out of stock or overstocking, all while improving overall efficiency.

What external data does AI use to improve inventory management?

AI-driven inventory management taps into a wide range of external data sources to boost both precision and efficiency. For instance, macroeconomic indicators such as inflation rates and GDP trends help account for shifts in market-wide demand. Seasonal and holiday data are also factored in to anticipate sales surges or slowdowns. Even weather forecasts are considered, as factors like temperature or rainfall can influence demand for specific products.

On top of that, AI delves into social media trends and consumer sentiment, uncovering emerging preferences that can shape inventory decisions. It also uses regional demographic data to align inventory strategies with the unique buying habits of local markets. By blending these insights with real-time market trends, AI identifies hidden patterns, forecasts demand with greater accuracy, and helps avoid stock shortages or excess inventory.

How can businesses effectively implement AI-driven demand forecasting?

To get the most out of AI-driven demand forecasting, businesses need to start with a solid data foundation. This means collecting detailed historical sales data and incorporating external factors like social media trends, weather patterns, and economic indicators. These additional elements help the AI model detect nuanced demand trends. It's crucial to ensure the data is accurate, time-stamped, and stored in a centralized system that allows for real-time updates.

Once the data foundation is in place, begin with a small pilot project. Focus on a select group of products to test how well the system predicts demand. Use this phase to fine-tune the model and improve its accuracy. After achieving reliable results, integrate the AI forecasts into inventory management systems. This step can automate tasks like reorder alerts and stock level projections, streamlining operations.

For a smooth transition, clear communication and leadership support are key. Providing staff with proper training ensures everyone understands the new processes and can fully leverage the advantages of AI-driven forecasting.