43% of businesses lose sales due to inaccurate demand forecasts. Meanwhile, U.S. retail inventory accuracy averages just 63%. AI demand forecasting offers a solution by using real-time data - like weather, social media trends, and market shifts - to predict demand with precision and reduce errors by up to 50%. Companies implementing AI have seen inventory levels drop by 20–30% and stockouts decrease by 65%.

Key takeaways:

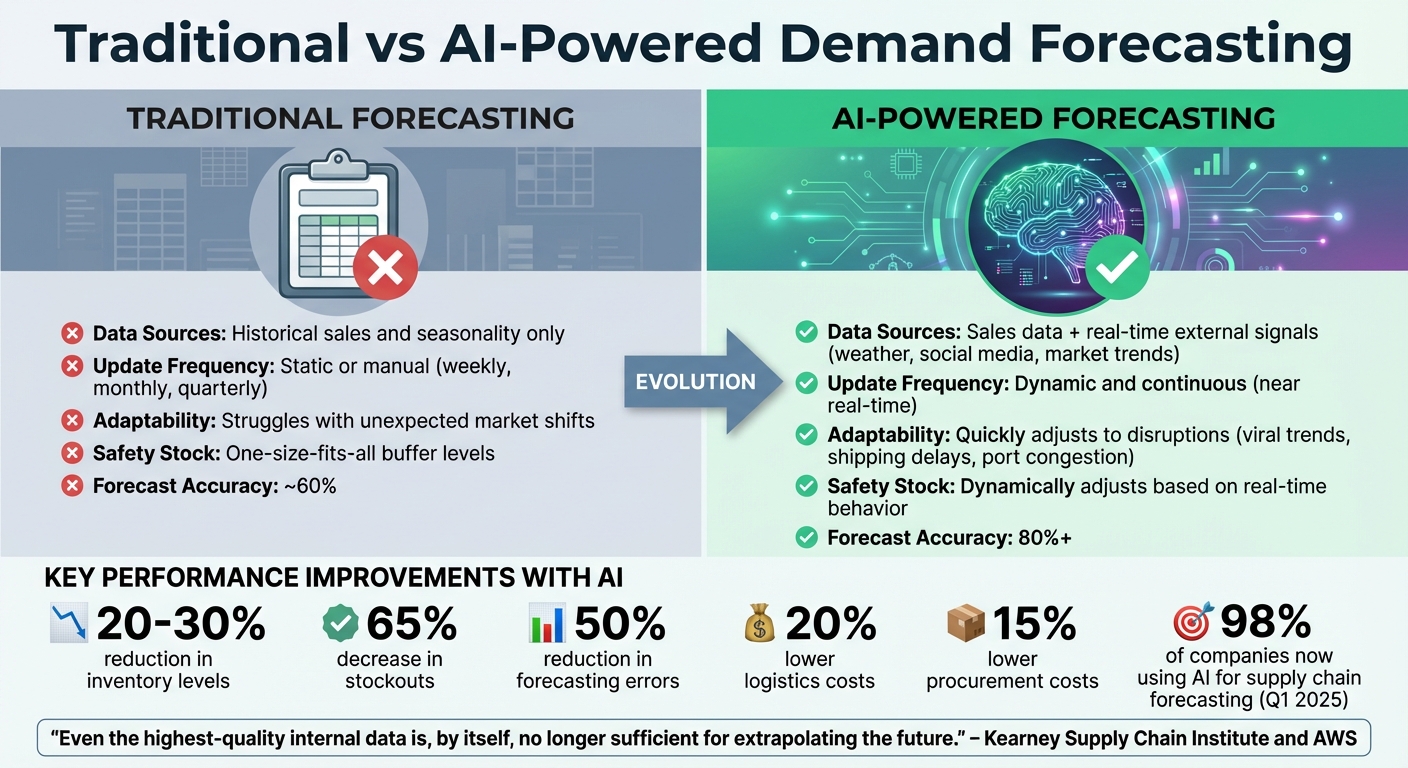

- AI uses machine learning, neural networks, and predictive analytics to improve forecast accuracy from 60% to 80%.

- It enables SKU-level predictions, automated reordering, and real-time inventory adjustments.

- Businesses save time, reduce excess stock, and improve cash flow while meeting demand efficiently.

With 98% of companies now using AI for supply chain forecasting, the time to switch from outdated methods is now.

AI Inventory Management: Predict Demand, Prevent Stockouts

sbb-itb-499c055

What Is AI Demand Forecasting

Traditional vs AI-Powered Demand Forecasting: Key Differences and Performance Metrics

AI demand forecasting uses artificial intelligence and machine learning to predict product demand by analyzing real-time data, historical trends, and external factors like weather or social media activity. Unlike traditional methods that depend on static spreadsheets or basic seasonal averages, AI systems continuously learn and update as new data comes in, making them far more dynamic. This ability to adapt in real time allows businesses to refine their demand predictions and respond faster to changes.

One key component of this shift is demand sensing, which focuses on short-term trends by using up-to-the-minute data to create precise forecasts, sometimes on an hourly basis. For example, if a TikTok trend suddenly drives interest in a product, AI can pick up on this social media activity and predict the surge in demand before it impacts sales.

"Even the highest-quality internal data is, by itself, no longer sufficient for extrapolating the future." – Kearney Supply Chain Institute and AWS

The results speak for themselves. Companies using AI forecasting see accuracy rates jump from 60% to 80%, while inventory levels drop by 20–30% and product shortages decrease by 65%. For instance, Idaho Forest Group slashed its forecasting time from over 80 hours to less than 15. Similarly, Novolex reduced its planning cycles from weeks to days and cut excess inventory by 16%.

| Feature | Traditional Forecasting | AI-Powered Forecasting |

|---|---|---|

| Data Sources | Historical sales and seasonality | Combines sales data with real-time external signals like weather and social media |

| Update Frequency | Static or manual (weekly, monthly, quarterly) | Dynamic and continuous (near real-time) |

| Adaptability | Struggles with unexpected market shifts | Quickly adjusts to disruptions like viral trends, shipping delays, or port congestion |

| Safety Stock | One-size-fits-all buffer levels | Dynamically adjusts based on real-time behavior |

Technologies Behind AI Demand Forecasting

AI forecasting relies on three main technologies: machine learning (ML), neural networks, and predictive analytics. Machine learning identifies patterns in historical data, such as noticing that rain in Seattle leads to a 40% spike in umbrella sales within 24 hours. Neural networks take it a step further by uncovering complex relationships that traditional models often miss, such as how weather, social media buzz, and local events combine to drive demand.

Predictive analytics turns these patterns into actionable forecasts. Advanced systems can automatically select the best forecasting model for each product by testing algorithms - like Moving Average or Exponential Smoothing - and choosing the one with the lowest error rate. This ensures both fast-moving products and steady sellers are forecasted accurately.

Retail giant Walmart uses AI-powered demand sensing to adjust inventory levels based on weather, local events, and customer behavior. For example, when a hurricane warning is issued in Florida, the system increases stock for essentials like batteries, bottled water, and canned goods before the rush begins.

Together, these technologies help businesses maintain the right stock levels while staying agile in the face of market changes.

Data Inputs for AI Forecasting

Strong AI forecasting depends on high-quality data. These systems pull from two main types of data: internal and external.

- Internal data includes historical sales records, inventory levels, promotional calendars, pricing history, and customer insights from CRM platforms. This provides the foundation for predictive models.

- External data expands the scope by incorporating weather forecasts, social media trends, macroeconomic indicators (like inflation rates), and geopolitical factors like shipping delays. Some platforms analyze over 200 external signals, improving forecast accuracy by 10–20% and reducing inventory by 5–10%.

For example, Asia's largest spice company improved forecasting accuracy by 30% and cut inventory waste by 20% by integrating data like festival calendars, regional weather patterns, and social media chatter about recipes. This allowed them to predict demand spikes weeks in advance.

Data quality is critical. AI systems amplify the impact of poor data, so it's essential to start with clean, structured historical data - ideally 12–18 months' worth. Additionally, syncing inventory data across warehouses, stores, and logistics partners in real time ensures the AI system has a single, reliable source of truth.

How AI Optimizes Stock Levels

AI-driven demand forecasting is revolutionizing inventory management, turning predictions into actionable strategies. Instead of relying on outdated spreadsheets or subjective guesses, businesses now use AI to decide what to order, when to order, and how much safety stock to keep. Traditional methods stick to rigid rules, while AI adapts using self-learning models that incorporate data like weather, social trends, and sales activity to refine predictions. This shift enables sharper insights into product-specific demand, automated reordering, and real-time inventory adjustments.

SKU-Level Demand Prediction

AI doesn't just predict demand for product categories - it drills down to specific variations like size, color, or style. This detailed analysis is especially important for multi-channel retailers, where demand can differ between online stores and physical locations. By analyzing historical sales, promotions, and even stockout events, AI identifies unique patterns for each SKU. It also pulls in external factors such as weather forecasts, social media buzz, competitor pricing, and local happenings to improve predictions.

Imagine a sudden social media trend making a specific product variation popular. AI can detect this spike and adjust forecasts before sales data even catches up. This level of precision helps businesses avoid overstocking one variation while running out of another. By syncing demand signals across online, in-store, and marketplace channels, AI eliminates the problem of "siloed" inventory, where one channel sells out while another holds excess stock.

With this granular understanding, automated replenishment takes inventory management to the next level.

Automated Replenishment

AI creates dynamic reorder points by constantly tracking sales trends, supplier performance, and lead time fluctuations. Unlike older systems that rely on fixed safety stock levels, AI adjusts these thresholds based on real-time data and risk assessments. It even evaluates supplier reliability using past performance data. For instance, if a vendor frequently delivers late, the system increases safety stock for those items, reducing the risk of stockouts.

When inventory hits a set threshold, AI generates purchase orders automatically. It factors in supplier variability and potential shipping delays to ensure timely deliveries. For unexpected situations - like a sudden demand surge or a supplier issue - AI alerts human planners to intervene.

Real-Time Inventory Adjustments

AI turns inventory management into a dynamic system that updates constantly with new data from transactions, shipments, and external signals. By incorporating live sales data, social media trends, weather updates, and economic indicators, AI picks up on subtle shifts that traditional models might miss.

When disruptions happen, AI recalculates safety stock and suggests immediate actions. Businesses can reroute inventory between warehouses or adjust purchase orders as needed. Centralized dashboards provide a clear view of stock levels across locations, making it easier to spot slow-moving items or potential stockouts.

The results speak for themselves. Companies using AI for inventory management report inventory reductions of 20% to 30%. Stockouts can drop by as much as 65%, while logistics and procurement costs decrease by 20% and 15%, respectively.

This real-time adaptability means businesses aren't locked into decisions made weeks ago. Instead, they can react to market changes as they happen, keeping stock levels balanced without overcommitting resources or losing sales due to shortages.

Benefits of AI-Driven Stock Optimization

AI-driven stock optimization offers clear operational and financial advantages that traditional methods simply can't match. While conventional approaches rely on static rules - like fixed reorder points and outdated safety stock formulas - AI adapts dynamically to the ever-changing demands of modern supply chains. This flexibility allows businesses to stay ahead of market volatility.

The financial upside is hard to ignore. By lowering inventory levels, AI frees up working capital and reduces storage costs. At the same time, it minimizes lost revenue by significantly cutting product unavailability - stockouts have dropped by as much as 65% in some cases. Companies have also seen logistics costs fall by up to 20% and procurement expenses by up to 15%. Notably, 25% of organizations report that AI-driven solutions, like demand planning, contribute over 5% to their Earnings Before Interest and Taxes (EBIT).

Reducing Stockouts and Excess Inventory

AI shines when it comes to tackling stockouts and excess inventory. By analyzing real-time external signals, it moves beyond the limitations of category-level, weekly predictions. Instead, AI delivers SKU-level forecasts that are refreshed daily - or even hourly. This level of detail allows businesses to react quickly to demand spikes, preventing lost sales opportunities.

Take Bargreen Ellingson, for example. The company reduced excess inventory by $2 million, improved fill rates for high-turn items by 5%, and slashed stockouts to just one-third of their previous levels. These results highlight a transformative shift in how inventory is managed.

Automated replenishment systems further enhance efficiency by eliminating manual guesswork. These systems alert planners to purchase orders that need immediate attention, whether to avoid stockouts or free up cash. When AI identifies potential issues, it provides actionable recommendations based on factors like supplier reliability, lead time variability, and current demand trends. These operational upgrades lead to even more accurate and reliable forecasts.

Better Forecast Accuracy

Forecasting accuracy is another area where AI outperforms traditional methods. While conventional forecasting models typically achieve around 60% accuracy, AI-driven solutions push that figure to 80% or higher. In some cases, forecasting errors have been reduced by as much as 50%.

A prime example is Asia's largest spice company. By transitioning from manual forecasting to AI, the company improved its forecast accuracy by 30% and cut inventory waste from expired products by 20%. The key difference lies in how AI processes data. Traditional models often rely on linear regression and intuition, whereas AI uses machine learning and deep learning algorithms that continuously adapt to new data.

"Even the highest-quality internal data is, by itself, no longer sufficient for extrapolating the future."

– Kearney Supply Chain Institute and AWS

This enhanced accuracy has a ripple effect throughout the supply chain. It leads to better production scheduling, optimized use of warehouse space, stronger supplier relationships, and allows planners to dedicate more time to strategic decision-making.

With 98% of companies now incorporating AI into their supply chains for forecasting and optimization as of Q1 2025, the conversation has shifted. It's no longer about whether to adopt AI - it's about how quickly businesses can implement it to stay competitive.

Implementing AI Demand Forecasting

Shifting from traditional forecasting methods to AI-driven systems might seem challenging, but with careful planning, it becomes much more manageable. A phased approach works best. By Q1 2025, 98% of companies were already using AI in their supply chains for inventory optimization and forecasting, making the steps to successful adoption clearer than ever.

At the heart of any AI forecasting system lies data quality and volume. To uncover meaningful seasonal patterns, you'll need at least 12–18 months of clean historical sales data. But relying solely on internal data isn’t enough - enriching it with external signals boosts accuracy and helps the system adapt to changing market conditions.

Seamless integration is another critical step. AI systems should connect with existing tools like ERP, POS, CRM, and WMS platforms to break down data silos and ensure real-time information flow. Many modern platforms can even sync AI-driven insights directly into ERP systems, automatically updating "Min/Max" targets and "Reorder Up To" quantities. To avoid overwhelming your team, start small - pilot the system with one product category or location, demonstrate its value, and then scale up. Once your systems are connected, the next focus is preparing your data for accurate forecasting.

Preparing Your Data

AI depends on clean, complete, and accurate data - flawed inputs will only lead to flawed outputs. Start by identifying your core data sources, such as historical sales, supplier lead times, seasonal trends, and supplier performance. Organize this information at the SKU level, factoring in details like size, color, and variation, and break it down by location (e.g., specific warehouses or stores). This level of detail allows for precise, localized forecasting.

Focus on data quality over quantity. Clean, structured, and consistent records are essential. For new products without historical data, consider backfilling by creating back-dated delivery records to give the AI a starting point. Tagging data with "Demand Events" - like Black Friday, flash sales, or local festivals - helps the AI distinguish between temporary spikes and organic growth. Don’t overlook supplier lead times; even a small error, like a two-day discrepancy, can disrupt AI-driven replenishment. Once your data is polished and organized, use it to evaluate your system's performance.

Measuring Performance

Tracking performance metrics is crucial to understanding how well your AI system is working. Focus on key indicators like forecast accuracy, inventory fill rate, and Days of Inventory on Hand (DIO).

- Forecast accuracy: Aim for 80% or higher. While traditional models typically hover around 60%, AI-driven solutions often achieve much better results.

- Inventory fill rate: This measures how often demand is met without stockouts. For example, in 2025, The Little Potato Company improved its fill rate from 90.9% to 98% using an AI-driven statistical model to adjust safety stock based on forecast deviation.

"Being able to adjust safety stock based on statistical modeling using history and forecast deviation instead of just several days coverage has improved our inventory fill rate from 90.9 to 98%" – Philip Yu, Senior Sales and Operations Manager

- Days of Inventory on Hand (DIO): Monitor this to ensure you’re not tying up capital in excess stock.

Set up thresholds to flag unusual demand spikes or drops for manual review. Short-term forecasts (like 3-month projections) are generally more reliable for preventing stockouts compared to longer-term ones. At first, review these metrics weekly. As your system stabilizes and your team gains confidence in the AI’s recommendations, you can adjust the review frequency.

Conclusion

AI-driven demand forecasting has become a game-changer for inventory management. By Q1 2025, a staggering 98% of companies have incorporated AI into their supply chains, achieving impressive results like 60–80% forecast accuracy, 20–30% reductions in inventory, and cutting forecasting errors by half.

Moving away from outdated spreadsheets to AI-powered tools has redefined how businesses manage stock. Instead of reacting to shortages or overstocking, companies now predict demand changes with precision. With features like SKU-level accuracy, automated restocking, and real-time updates, businesses can keep the right products on hand in the right amounts - freeing up cash flow and avoiding unnecessary markdowns. This shift is central to platforms like Forthcast, which makes these tools accessible for businesses of all sizes.

For e-commerce brands, Forthcast simplifies this transformation without the need for a specialized data science team. It provides 6-month demand forecasts, flags anomalies, sends smart reorder alerts, and includes a self-assessing accuracy engine that tracks both bias and error magnitude. These features deliver enterprise-grade forecasting without the complexity.

The cost of delaying AI adoption is steep. Poor inventory forecasting leads to missed sales for 43% of businesses, while inventory accuracy across U.S. retail averages only 63%. By starting with clean historical data and keeping an eye on key metrics like forecast accuracy and Days of Inventory on Hand, businesses can unlock measurable improvements in efficiency and profitability.

The future of inventory management isn’t about working harder - it’s about working smarter. AI handles the heavy lifting of baseline forecasts, giving you the freedom to focus on strategic decisions that drive growth. Embrace AI-driven forecasting now to create a more agile and efficient supply chain that’s ready for whatever comes next.

FAQs

How does AI enhance demand forecasting accuracy compared to traditional methods?

AI significantly improves demand forecasting by processing large amounts of real-time and external data, spotting trends, and dynamically updating predictions. Traditional methods often depend on static historical data, which can fall short when dealing with sudden market changes or seasonal shifts. AI, on the other hand, adjusts to these variables in real-time.

This adaptive capability not only cuts down forecasting errors but also helps businesses avoid stockouts, reduce surplus inventory, and streamline supply chains. With AI, companies gain the ability to make smarter, data-backed decisions, ensuring they balance inventory levels while effectively meeting customer needs.

What data is essential for accurate AI demand forecasting?

Accurate AI demand forecasting thrives on a combination of historical sales data and external influences. Historical sales lay the groundwork by highlighting trends and seasonal patterns, while external factors - like weather conditions, economic shifts, and changes in consumer behavior - fine-tune these predictions to reflect real-world dynamics.

On top of that, internal data plays a key role. Information such as current inventory levels, lead times, and sales velocity helps businesses determine the right stock levels and when to reorder. External signals, such as natural disasters or major events, add another layer of precision, helping companies minimize stockouts, prevent overstocking, and make smarter supply chain decisions.

How can businesses start using AI for demand forecasting?

To kick off AI-driven demand forecasting, the first step is gathering and organizing your data. This includes pulling together details like sales history, inventory levels, lead times, and even external factors such as market trends. Having accurate and well-structured data is critical for the AI platform to deliver reliable forecasts.

Next, select an AI-powered tool that fits your needs. For instance, platforms like Forthcast offer features such as demand prediction, reorder alerts, and anomaly detection. Once you've chosen your tool, upload your historical data and configure key settings like safety stock levels and lead times. Regularly evaluate the accuracy of the forecasts and adjust the settings as needed to ensure the system continues to improve over time.

Finally, take those AI-generated forecasts and weave them into your inventory management and supply chain processes. Doing so allows you to maintain optimal stock levels, avoid stockouts, and cut down on overstocking. By relying on these data-driven insights, businesses can streamline operations and enhance overall efficiency.