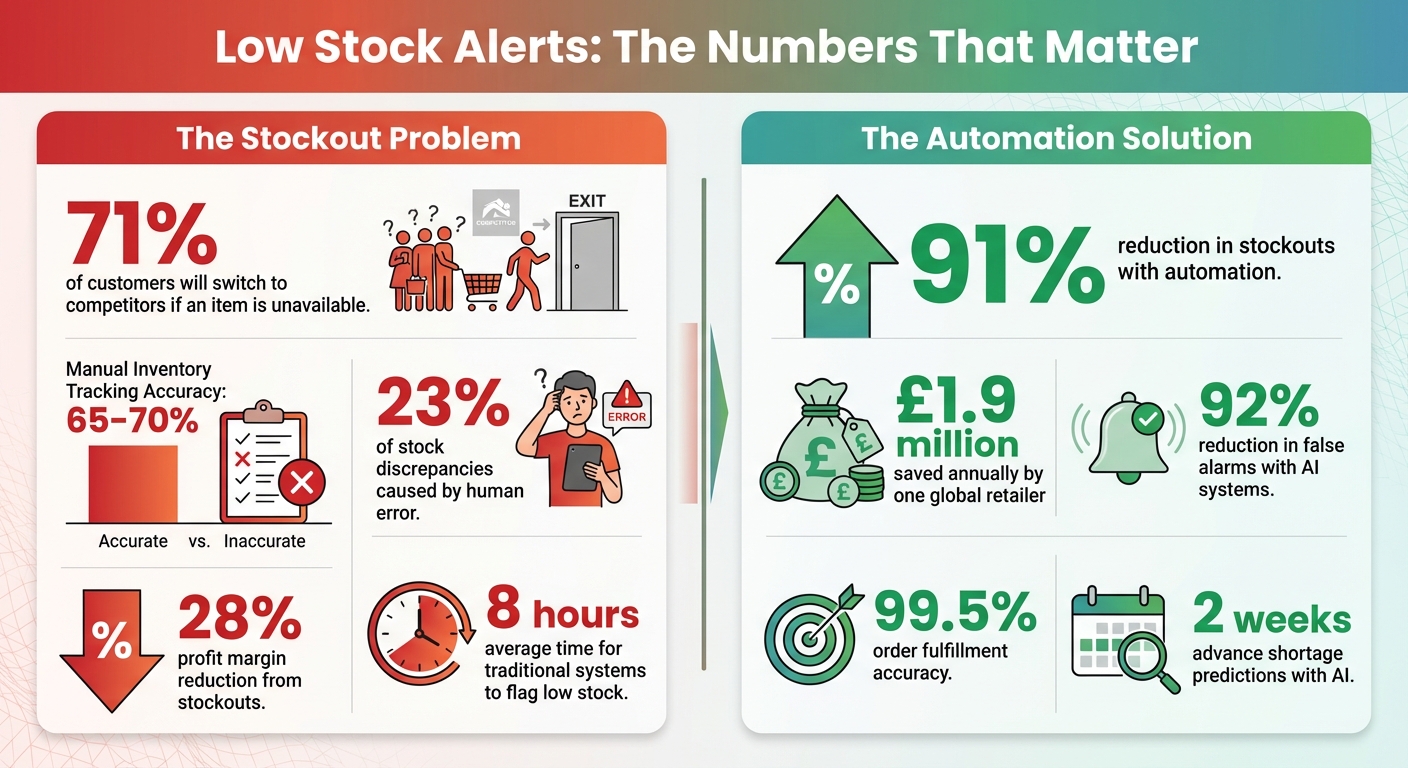

Stockouts cost businesses both revenue and customer trust. 71% of customers will switch to competitors if an item is unavailable, and manual inventory tracking, with only 65-70% accuracy, often leads to errors. Automating low stock alerts can reduce stockouts by 91%, save businesses millions annually, and streamline inventory management. These alerts notify you when stock levels fall below a set threshold, allowing timely reorders. Advanced tools, powered by AI, predict shortages weeks ahead, adjust for demand fluctuations, and automate purchase recommendations, ensuring optimal stock levels. Here's how to set up and benefit from automated low stock alerts.

The Impact of Automated Low Stock Alerts on Business Performance

AI Inventory Management: Predict Demand, Prevent Stockouts

What Are Stockouts and Low Stock Alerts?

A stockout occurs when your inventory hits zero while customers are still looking to buy. This can lead to unfulfilled orders, cancelled sales, and backorders - all of which can hurt your revenue and reputation.

Low stock alerts, on the other hand, are automated notifications that kick in when your inventory falls below a certain level. Instead of finding out too late that you're out of stock, these alerts give you a heads-up, so you can reorder in time.

Two key numbers make these alerts work effectively: the reorder point and safety stock. The reorder point is calculated as (average daily usage × lead time) plus safety stock. Safety stock acts as a buffer for unexpected demand. For example, if you sell 50 units daily, your supplier takes 5 days to deliver, and you keep 100 units as safety stock, your reorder point would be 350 units. Knowing these figures is critical because stockouts come with steep costs, both financially and operationally.

The Real Costs of Stockouts

Running out of stock can cause a domino effect of problems. The most immediate hit is lost revenue from orders you can’t fulfil. But it doesn’t stop there - customers may lose trust in your business, which can have long-term consequences.

The financial impact is no small matter. For example, one global retailer saved £1.9 million annually and reduced stockouts by 91% after automating inventory management. Without such systems, businesses can see profit margins shrink by as much as 28%, thanks to costly measures like rush orders, expedited shipping, and emergency sourcing. Manual tracking doesn’t help much either - it’s only about 65–70% accurate, with human error causing 23% of stock discrepancies. These shortages often aren’t caught until it’s too late.

Operationally, stockouts waste time and resources. Teams end up dealing with customer complaints, fixing orders, and rushing deliveries. Traditional inventory systems lag behind, taking an average of 8 hours to flag low stock.

How Low Stock Alerts Function

Now that we’ve covered the basics, let’s dive into how low stock alerts actually work.

These alerts are triggered when your inventory reaches the reorder point, which includes your safety stock. When stock hits this critical level, the system sends a notification so you can reorder before you run out. Modern inventory systems track stock levels across all channels, warehouses, and product variations in real time.

Alerts can show up in your email, Slack, or even as an SMS. Some systems take it a step further by automating tasks like creating draft purchase orders or notifying suppliers. This shifts inventory management from being reactive to proactive. Advanced AI systems make things even smarter by predicting shortages weeks in advance, adjusting thresholds for factors like seasonality, promotions, and fluctuating demand. These systems can cut false alarms by 92% and achieve 99.5% order-fulfilment accuracy, ensuring you only reorder when it’s absolutely necessary.

How to Set Up Automated Low Stock Alerts

Automated low stock alerts can streamline inventory management, but setting them up requires careful planning and accurate data. The process involves three key steps: organising your inventory data, calculating reorder points and safety stock, and creating alert rules tailored to your needs.

Organising Your Inventory Data

Before automation can begin, your inventory data needs to be clean and well-structured. Start by conducting a thorough audit of your stock, either through a physical count or by exporting data from your system. Gather historical sales data (e.g., daily or weekly sales per SKU), supplier lead times (average and maximum in days), and current stock levels across all warehouses.

Once collected, organise this data in a centralised spreadsheet or inventory system. Include columns for SKU ID, product name, average daily sales over the past 30 to 90 days, lead time, safety stock levels, and current stock on hand. If you're using platforms like Shopify, you can export this data via CSV or use API integrations to minimise manual errors. After structuring the data, categorise your SKUs into A/B/C classes based on sales velocity. For example, A-class items might represent the top 20% of products by revenue, helping you focus on the most critical stock when setting up alerts.

Modern inventory platforms often integrate with systems like SAP or NetSuite and feature visual workflow builders that can reduce setup time significantly. Test your data by running it alongside your current system for about three weeks to identify and fix any inconsistencies before going live.

With your data in order, you’re ready to calculate reorder points and safety stock levels.

Calculating Reorder Points and Safety Stock

To determine when to reorder, use this formula: ROP = (Average Daily Usage × Lead Time) + Safety Stock. This ensures you reorder stock at the right time, while safety stock acts as a buffer against unexpected demand or delays.

Safety stock itself requires a separate calculation: Safety Stock = (Max Daily Usage × Max Lead Time) - (Avg Daily Usage × Avg Lead Time). For instance, if your maximum daily usage is 20 units and the maximum lead time is 10 days (200 units), and your average usage is 10 units with an average lead time of 7 days (70 units), your safety stock would be 130 units.

For seasonal products, increase your average usage by 1.5 during peak times, such as the holiday season. Fast-moving items may require higher safety stock to account for variability, which can be calculated using the standard deviation of daily sales, multiplied by a Z-score for your desired service level (usually 95%), and the square root of lead time. If your supplier is unreliable, consider increasing lead times by 20% to add an extra buffer.

Once you’ve established these thresholds, you can move on to configuring automated alert rules.

Setting Up Alert Rules

Set your alert threshold slightly below the reorder point. For example, if your reorder point is 90 units, trigger the alert at 70 units to allow for some extra time.

Customise thresholds based on the characteristics of each SKU. Products with low variability might only need alerts set at 1.5 times their lead time demand, while high-variability items may require thresholds set at 2 to 3 times the lead time demand. During promotional campaigns, raise thresholds by 20–50% to account for increased demand. For instance, if your usual alert level is 50 units, you might set it to 75 units during a campaign.

Modern systems offer multi-channel notifications via email, SMS, or Slack, and some can even generate draft purchase orders automatically when stock levels fall below critical thresholds. Begin by setting up alerts for your A-class SKUs - these are typically your most valuable or fastest-selling items. Roll out the alerts in phases, starting with 50 SKUs, and then expand to 500. Monitor weekly reports to refine thresholds based on actual performance, especially during seasonal peaks or promotions.

Advanced AI-driven platforms can predict shortages up to two weeks in advance, adjusting thresholds automatically by analysing real-time patterns. This kind of predictive capability can make stock management even more efficient.

sbb-itb-499c055

Using Automation and AI-Driven Tools

Once you've set up reorder points and alert rules, automation and AI can take inventory management to the next level. Instead of relying on static thresholds that need constant manual updates, AI tools dive into historical sales data, seasonality, promotions, and external factors to predict demand. This dynamic approach means you can get alerts well in advance - sometimes days or even weeks - before a potential stockout, rather than scrambling when inventory levels hit critical lows. Let’s explore some key AI features that make inventory management smarter and more efficient.

AI-Driven Forecasting and Stock Projections

AI-powered forecasting doesn’t just skim the surface; it digs deep into historical sales data at the SKU level, ideally covering at least a year. It factors in prices, promotions, returns, and even channel-specific trends to uncover demand patterns. Beyond internal data, it also considers external signals like UK-specific seasonality (think Black Friday, Boxing Day, and summer bank holidays), weather conditions, and your marketing plans to create demand models that go far beyond basic averages.

Here’s a real-world example: a global retailer reported slashing stockouts by 91% and saving £1.8 million annually on inventory costs by switching to AI-driven reorder adjustments. These systems combine demand forecasts with current inventory, in-transit stock, committed orders, supplier lead times, and constraints like minimum order quantities. The result? A clear, forward-looking view of when stock levels might dip too low or exceed operational limits. Tools like Forthcast provide six-month demand and stock projections at the SKU level, helping you order early to avoid missed sales while keeping excess inventory in check.

Automating Reorder Recommendations

Automation takes things a step further by generating concrete purchase recommendations. These systems constantly compare real-time stock levels - including on-order inventory - against each SKU’s reorder point. If projected stock for a delivery date is expected to drop below that threshold, the system suggests an order, factoring in supplier requirements like minimum quantities, pack sizes, and budget constraints. For instance, you might get a daily prompt recommending 240 units of a top-selling SKU to maintain a 97% service level in the UK.

Platforms like Forthcast refine this process with smart reorder suggestions and low stock alerts. You can even customise service levels by SKU category - prioritising higher availability for bestsellers and leaner stock for slower-moving items. This approach shifts the focus from reactive monitoring to exception-based management. Instead of juggling multiple systems, your team can review a consolidated queue of alerts and recommendations, often delivered through email or Slack. This frees up planners to focus on strategic tasks like launching new products or negotiating supplier terms.

Monitoring and Refining Alerts with Forthcast

Even with automation in place, regular monitoring and fine-tuning are essential. Forthcast’s anomaly detection flags unexpected sales spikes - like those triggered by a viral post - or sudden drops, allowing you to investigate and adjust forecasts or thresholds as needed. Its forecast tracking tools measure accuracy at the SKU level, using error and bias metrics to pinpoint areas that might need tweaking.

Best Practices for Ongoing Improvement

To keep your system responsive and dependable as your business expands and market dynamics evolve, ongoing testing, monitoring, and adjustments are essential. These steps build on the groundwork laid during setup, ensuring your supply chain remains steady and reliable.

Testing Alert Systems Before Launch

Before rolling out automated alerts across your product catalogue, it’s crucial to run a parallel testing phase for at least three weeks. During this period, compare the performance of automated alerts with your existing manual processes. Conduct weekly cycle counts on critical SKUs to validate system accuracy. Pay attention to which system identifies potential stockouts first and measure any discrepancies in on-hand balances or missed alerts. Begin with your A-class SKUs - those high-value or fast-moving items - to confirm the system’s effectiveness before scaling it up.

Keep in mind the limitations of manual counts. Use variance analysis to compare predicted stockouts with actual occurrences. If the variance exceeds 10%, consider factors like batch processing delays - manual systems often lag by up to 8 hours - and adjust your alerts to trigger earlier, ideally 14 days before a potential shortage. Aim for a variance of less than 5% between system records and actual stock levels.

Tracking Key Performance Metrics

Once your alert system is live, monitoring key performance indicators (KPIs) weekly is vital to measure its effectiveness. Focus on metrics such as stockout rates (keep these under 2%), days of stock on hand (typically 30–60 days for e-commerce), and emergency shipment costs (aim for under 5% of total orders). Regular KPI monitoring ensures your system stays on track.

Set up automated reports to assess alert accuracy - measuring the ratio of useful alerts to total alerts - and order fulfilment accuracy, which should ideally hit 99.5% or higher. AI-driven systems offer significant operational improvements, reducing false alerts by up to 92%. Tools like Forthcast’s real-time tracking can help you fine-tune alert parameters as market conditions shift. Use SKU-level forecast accuracy metrics, including error and bias measurements, to identify areas that need adjustment.

Adjusting Thresholds Based on Trends

After evaluating performance through KPIs, refine your alert thresholds to keep up with changing demand patterns. Static thresholds can quickly become outdated. Review and update your settings monthly, using 12-month sales data along with external factors like promotions, seasonality, and supplier performance. For high-demand periods - such as Black Friday, Boxing Day, or summer bank holidays - raise thresholds by 20–30% to prevent stockouts. During slower months, lower thresholds to avoid overstocking.

Supplier lead times are another critical factor. If a supplier’s delivery schedule becomes less reliable or starts taking longer, increase safety stock and adjust reorder points for those SKUs accordingly. Focus on higher thresholds for your bestsellers and flagship products to minimise the risk of running out, while maintaining leaner stock levels for slower-moving items. Forthcast’s anomaly detection and custom enrichment tools can automate many of these adjustments, flagging unusual patterns and helping you respond swiftly to changing conditions.

Conclusion

Automated low stock alerts are changing the game for e-commerce businesses, making inventory management smoother and more reliable. By removing the need for constant manual checks, these systems save time, improve accuracy, and ensure stock levels are just right to avoid costly stockouts.

Taking this a step further, AI-powered tools like Forthcast bring even more efficiency by predicting demand before inventory dips too low. With features like demand forecasting, anomaly detection, and SKU-level analysis, these tools create reorder points that adapt to real-world changes - whether it’s seasonal trends, promotional spikes, or delays from overseas suppliers. This forward-thinking approach reduces the need for last-minute shipments, aligns purchasing with actual demand, and helps businesses cut holding costs while protecting profit margins. AI-driven alerts can significantly lower stockout rates and improve order accuracy, which ultimately boosts profits across sales channels.

To get started, focus on your most critical SKUs - top sellers, seasonal favourites, or items with longer lead times. Set up alerts based on thresholds informed by recent sales data and supplier timelines. Platforms like Forthcast make this process even easier. It’s free to use, integrates seamlessly with popular e-commerce systems, and lets you track metrics like stockout rates and stock turnover over a few months. This allows you to fine-tune your alert settings based on real performance, making inventory management smarter and more effective.

FAQs

How do automated low stock alerts work to prevent running out of stock?

Automated low stock alerts are a smart way to keep your inventory in check. They notify you the moment stock levels dip below a predefined threshold, giving you ample time to reorder before running out. This system ensures your products stay available, reduces the chance of missed sales, and keeps your customers happy by always meeting their needs.

These alerts also simplify the reordering process. By cutting down on manual monitoring, they save time and effort, freeing up resources for you to concentrate on growing your business without worrying about stock shortages.

How can I set up automated low stock alerts effectively?

To set up automated low stock alerts, begin by using a forecasting tool like Forthcast to examine sales trends and estimate when inventory might dip too low. Establish a minimum stock threshold for each product (SKU) by considering your sales patterns and the service level you aim to maintain.

Next, configure alerts to activate when stock levels near this threshold. This ensures you have enough time to reorder before running out. Choose how you'd like to receive these notifications - whether through email, a mobile app, or another method that suits you best. Make it a habit to regularly review and tweak your thresholds to reflect shifts in demand or seasonal patterns, keeping your alerts as precise and useful as possible.

How does AI enhance inventory management and demand forecasting?

AI is transforming inventory management and demand forecasting by digging into historical data, spotting trends, and adjusting to market shifts. This leads to better demand predictions, enabling businesses to keep stock levels just right - avoiding the pitfalls of overstocking or running out of stock.

With the ability to automate intricate calculations and learn from fresh data, AI ensures that inventory decisions are based on solid data and run efficiently. For e-commerce businesses, this translates to higher profitability and a more seamless supply chain.